Slides and guides are the most and fastest wearing parts in machines.

Attachments

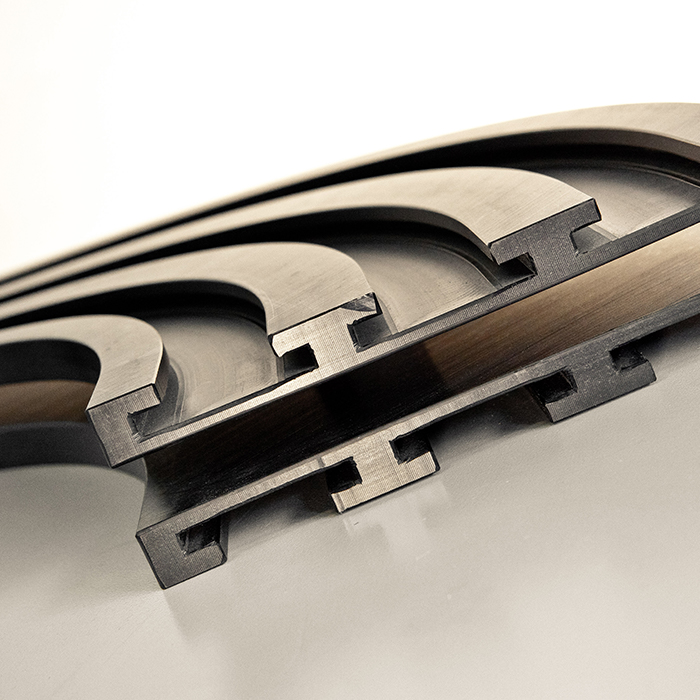

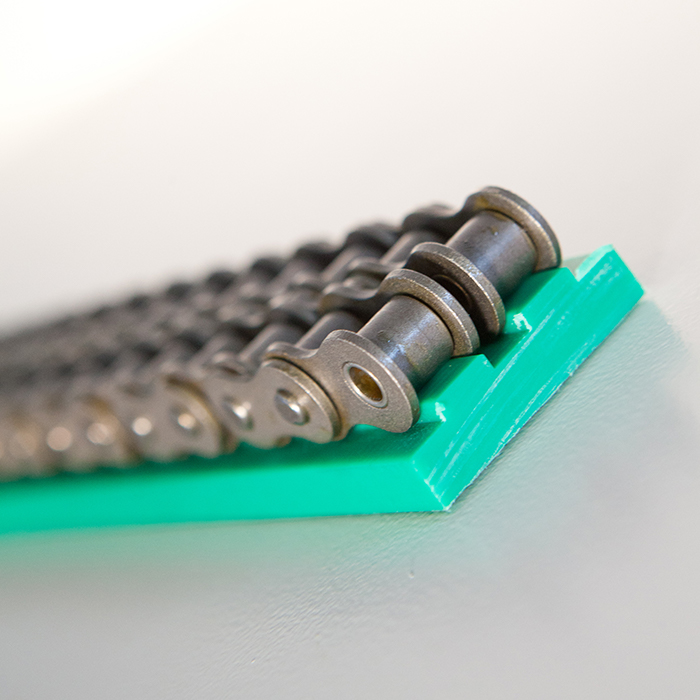

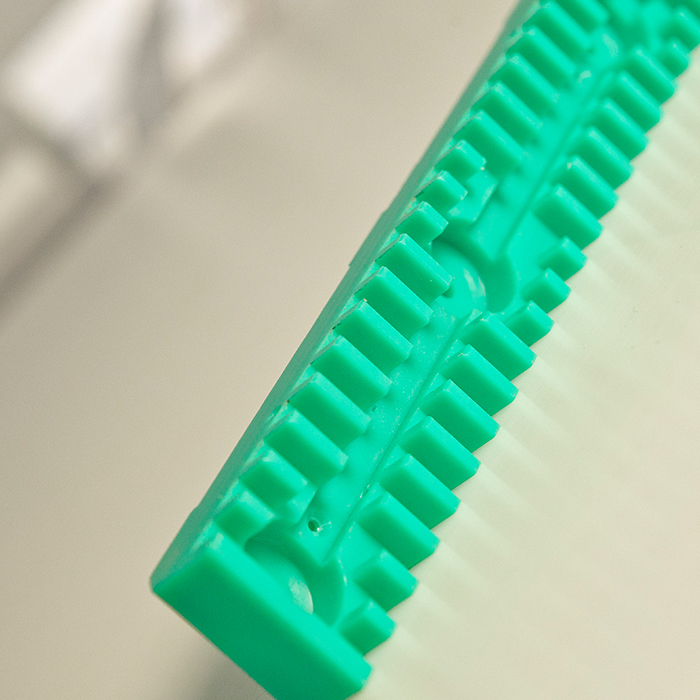

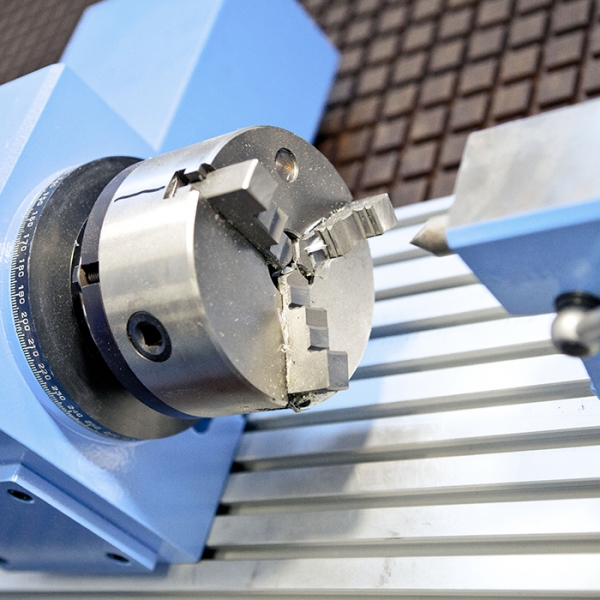

Archimedes-Folder-Plastics-2024-ENG.pdfSlides and guides are the most and fastest wearing parts in machines. For this reason, they require the lowest possible coefficient of friction and very high resistance to wear (abrasion). The main material used for slides and guides is polyethylene PE1000; PE-UHMW with an ultra high molecular weight. This material ensures a very long service life of the guides or sliding elements themselves, so we can avoid machine downtime due to their replacement.

For less demanding applications, high molecular weight polyethylene PE500; PE-HMW is used.

For very demanding, even extreme operating conditions, materials with lubricants or oil are used. One such material is a material with a solid lubricant and will therefore meet the requirements of even the most difficult applications.

In the case of slides or guides operating at elevated temperatures, we can use materials from a group of constructional or high-temperature materials with modifications.

Zobacz również

Machine casings

10,00złIn the case of machine casings, polycarbonate (PC) is used as the basic material due to its mechanical values, in ...Gear wheels

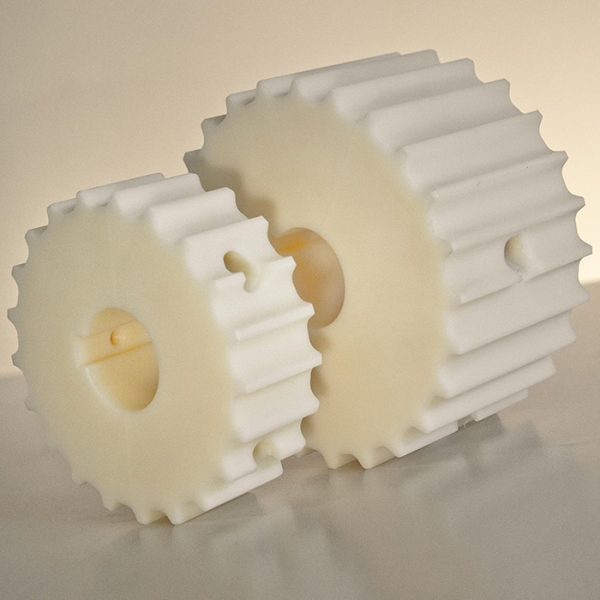

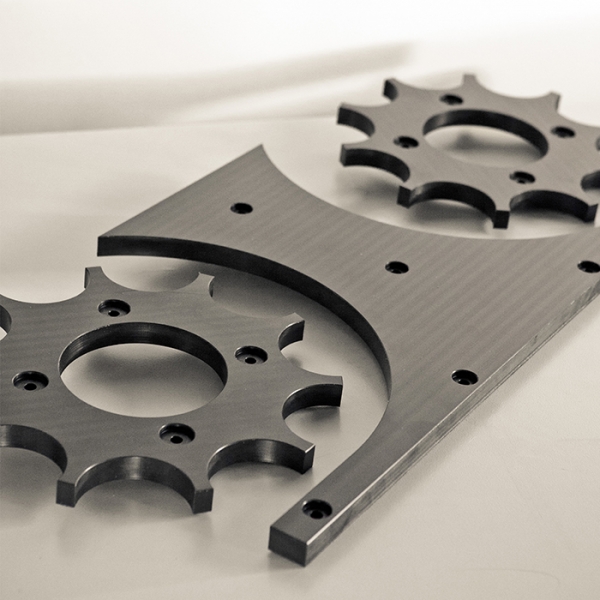

10,00złGear wheels are mainly used to transfer the drive to other gears, belts and chains.

Zobacz również

Gear wheels

10,00złGear wheels are mainly used to transfer the drive to other gears, belts and chains.Machine casings

10,00złIn the case of machine casings, polycarbonate (PC) is used as the basic material due to its mechanical values, in ...