Under-belt scrapers are devices used to clean and protect conveyor belts.

Under-belt scrapers are devices used to clean and protect conveyor belts. Rosta’s tensioners installed on both sides provide an automatic tensioning system that guarantees ideal blade pressure on the belt. The blades are made of polyurethane or tungsten carbide. They ensure long trouble-free operation.

Benefits of the scrapers:

- minimization of product loss

- no interruptions in conveyor operation due to the need to clean the area around

- less usage of the conveyor belt

- no loss of conveyor productivity

- increase in the service life of the rollers and conveyor drives

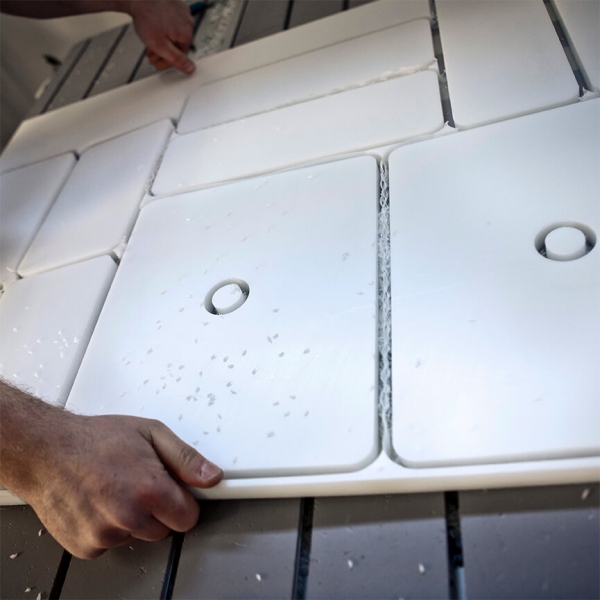

The scrapers consist of mounting plates, beam handles, Rosta tensioners and blades.

They are used mainly in the mining industry, aggregate mines or gravel pits. They are also successfully used in cement factories, recycling factories and wood industry (in sawmills).

Pollution caused by the lack of use of under-belt scrapers can lead to a threat to the safety of employees and the environment. This is a solution that is simple, cheap and effective. The blades, also called scrapers, can be made of polyurethane or tungsten carbide.

Other parameters:

- easy to install, operate and clean

- a triple polyurethane blade with a hardness of 90ShA or a 2 mm thick tungsten carbide blade

- the special blade mounting system enables easy and quick blade changes

- adjustable mounting plate spacing

- robust design for long trouble-free operation

- available in 7 standard sizes – customized sizes possible

- a scraper can be purchased with an assembly service

- short deadlines for implementation

- special scrapers can be made to suit customers application.

Zobacz również

Polyamide PA

10,00złPolyamide (PA) is a construction material whose properties allow it to be used in a very wide range of machine ...

Zobacz również

Polyamide PA

10,00złPolyamide (PA) is a construction material whose properties allow it to be used in a very wide range of machine ...