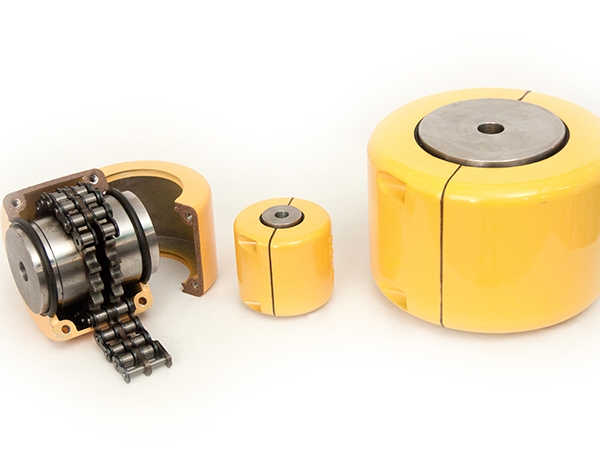

Overload couplings are used to disconnect the drive immediately after exceeding the set torque limit.

Overload couplings are used to disconnect the drive immediately after exceeding the set torque limit. The available models differ in mounting and reconnection options. They are not damaged after their activation. Prepared at the factory to the customer’s specified shaft diameters.

Overload couplings are used in industrial drives, from miniature laboratory equipment through pumps, machine tools to heavy machines in the mining industry.

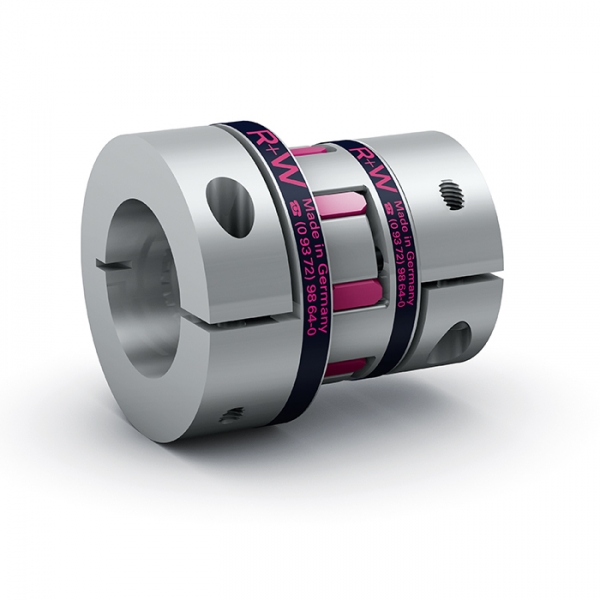

SL series

- moments of disconnection: 10 – 700 Nm

- holes’ diameters: 12 – 60 mm

- automatic switch-on

- low mass and moment of inertia

- corrosion resistant

- easy torque adjustment

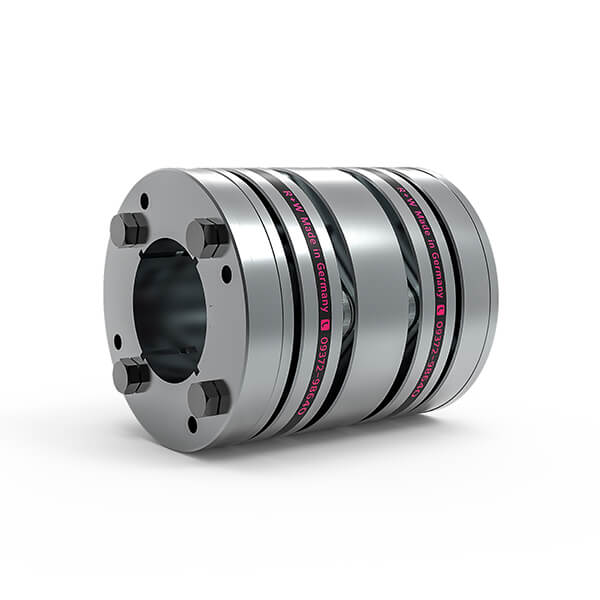

ST series

- moments of disconnection: 200 – 250 000 Nm

- holes’ diameters: 30 – 340 mm

- complete disconnection when the preset torque is exceeded

- robust, compact design

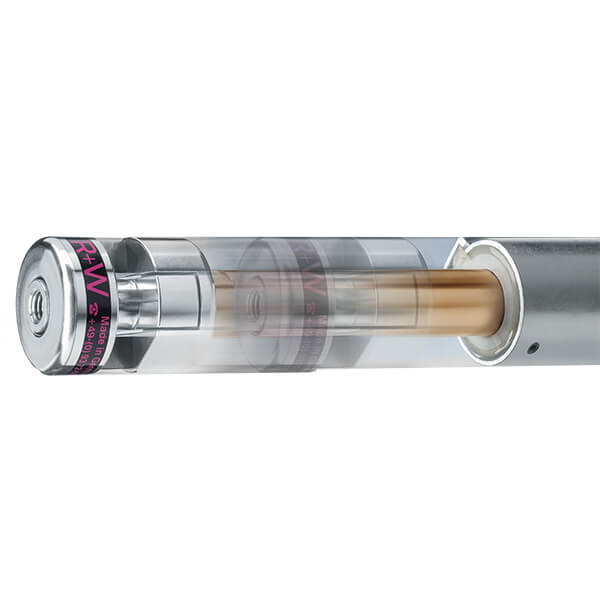

SK series

- disconnection moments: 0.1 – 2800 Nm

- holes’ diameters: 3 – 100 mm

- low residual friction after disconnection

- automatic or manual switch-on

- non-separable version as overload detector

ESL Series

- economic execution without torque control

- holes’ diameters: 6 – 38 mm

- transferred moments: 1 – 150 Nm

- automatic switch-on

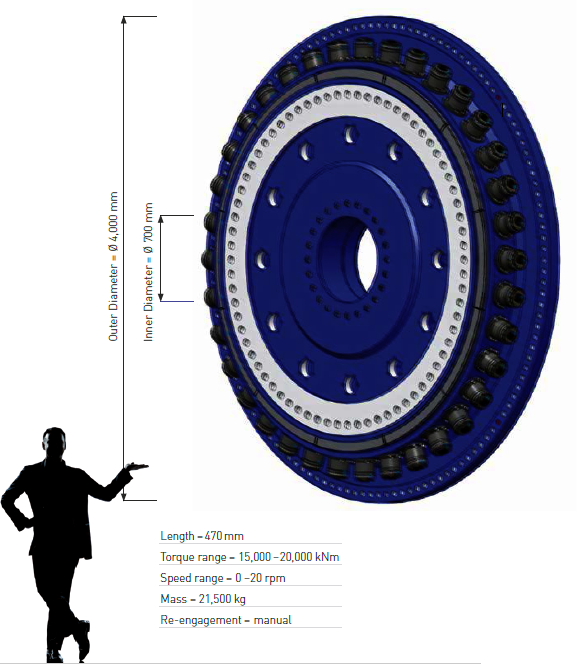

R+W engineers designed the STF 20000 overload coupling, which is 4 meters in diameter. The coupling was used as a protection for two 6MW motors, whose task is to test wind turbines. This solution has a chance to be included in the Guinness Book of Records as the largest overload coupling in the world.

R+W is very often involved in innovative projects. It is the industry leader in terms of technology and new implementations.

40% of R+W’s sales are couplings manufactured to individual customer orders.

Zobacz również

Linear joints

10,00złLinear joints of the LK series are a patented component by R+W company for the transmission of axial compressive ...Electromagnetic couplings with brake

10,00złThe Bonfiglioli’s electromagnetic coupling with a brake is a compact device enclosed in a support with IP54 protection.Sliding couplings

10,00złChiaravalli's sliding overload couplings are simple in design and operation.Disk couplings for R+W servo drives

10,00złR+W's many years of experience in the field of precision bellow couplings and the growing market demand for precision ...Bellow blacklash-free couplings

10,00złBellow blacklash-free couplings from R+W company are made of clamping hubs permanently connected with stainless steel bellows.Disc blacklash-free couplings

10,00złThe LP series disc couplings from R+W are made entirely of steel.Gear couplings

10,00złGear couplings manufactured by R+W belong to the group of torsionally rigid couplings.Chain couplings

10,00złChain couplings consist of two chain wheels connected by a two-row roller chain.Transmission shafts

10,00złR+W's backlash-free transmission shafts enable torque transmission between connected devices up to 6m away.Blacklash-free couplings

10,00złThe R+W manufacturer's backlash-free coupling consists of two hubs and an elastomer hub, which splits a insert.

Zobacz również

Linear joints

10,00złLinear joints of the LK series are a patented component by R+W company for the transmission of axial compressive ...Gear couplings

10,00złGear couplings manufactured by R+W belong to the group of torsionally rigid couplings.Unidirectional couplings CTS

10,00złIn our offer you will find high quality unidirectional couplings of the Italian brand C.T.S.Chain couplings

10,00złChain couplings consist of two chain wheels connected by a two-row roller chain.Electromagnetic couplings with brake

10,00złThe Bonfiglioli’s electromagnetic coupling with a brake is a compact device enclosed in a support with IP54 protection.Transmission shafts

10,00złR+W's backlash-free transmission shafts enable torque transmission between connected devices up to 6m away.Blacklash-free couplings

10,00złThe R+W manufacturer's backlash-free coupling consists of two hubs and an elastomer hub, which splits a insert.Disc blacklash-free couplings

10,00złThe LP series disc couplings from R+W are made entirely of steel.Sliding couplings

10,00złChiaravalli's sliding overload couplings are simple in design and operation.Bellow blacklash-free couplings

10,00złBellow blacklash-free couplings from R+W company are made of clamping hubs permanently connected with stainless steel bellows.