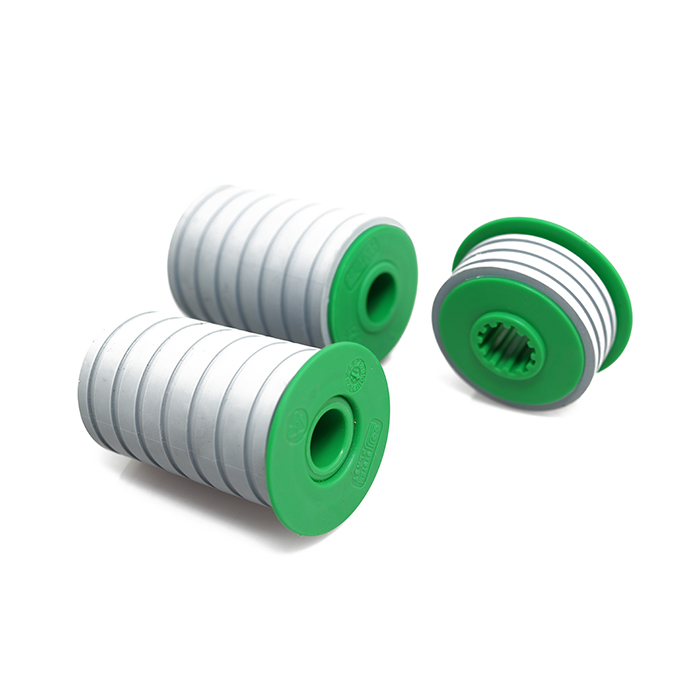

Conveyor rollers are designed to support plate chains and modular belts on the return part of the conveyor.

Attachments

KOMPONENTY DO TRANSPORTERÓW 06_2011.pdfConveyor rollers are designed to support plate chains and modular belts on the return part of the conveyor. They provide solid and reliable support and ensure stable, pulsation-free operation.

Material of rollers:

- polyethylene PEHD,

- self-draining polyamide PA,

- polypropylene PP,

- thermoplastic rubber TPR used to cover rolls.

Production range:

- external diameters of rolls from D39mm to D66mm (up to D75mm for rolls with flanges),

- diameters of holes fixed on axes from d12mm to d20mm,

- length from L31mm to L84.5mm.

Note – recommended minimum diameter for support rollers is D50mm, rollers with TPR rubber coating.

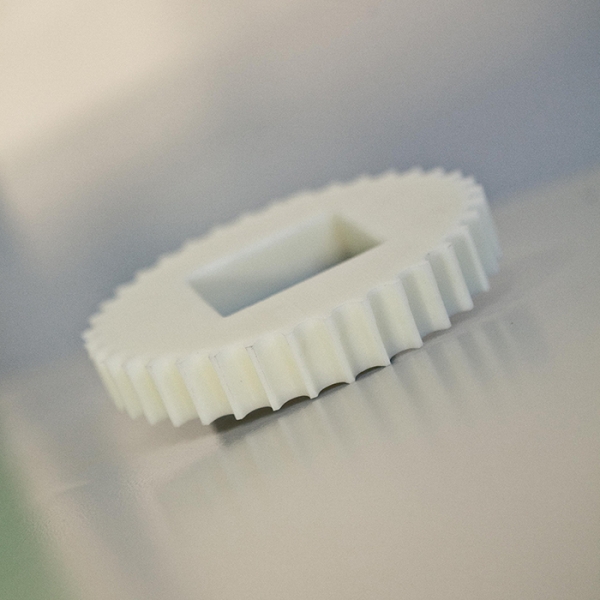

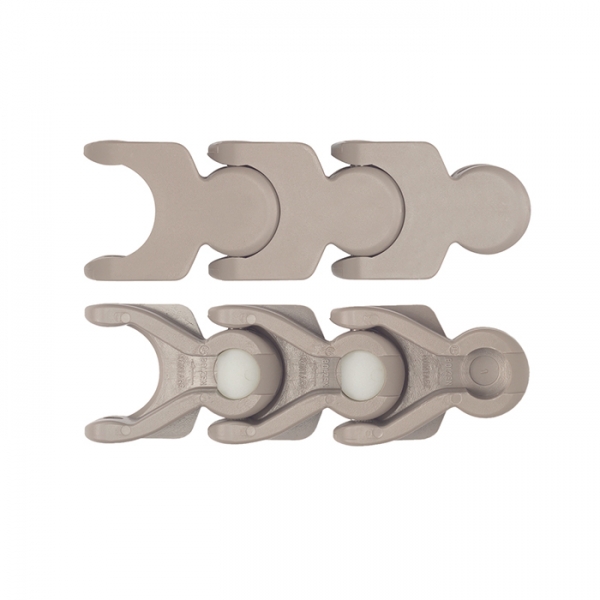

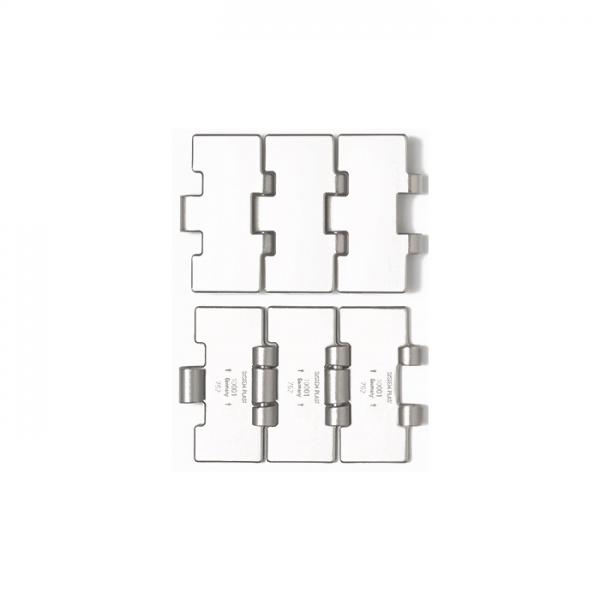

Roller modules – transfer modules serve as transitions fillings between conveyors.

They facilitate smooth, collision-free passage of products through so called dead zones in conveyors.

The construction of the modules (one-sided “nose”) makes it possible to install them as close as possible to drive or return wheels.

Roller modules are made of such materials as:

- acetal – module supports and rollers

- stainless steel AISI 304- pins, screws, washers, micro bearings,

- stainless steel AISI 304 – full rollers with micro bearings.

Production range:

- module widths – 85mm, 115mm, 154mm, 225mm

- lengths of modules, number of rows of rolls – R2 37.3mm/51mm, R3 49.6mm/39mm, R4 79mm, R5 73.6mm.

During installation, depending on the length of the transfer passage, it is possible to use different configurations of modules, e.g. R2/R2, R2/R3 etc.

Interactive online catalogue with editing of DXF, 3D drawings:

Zobacz również

Bearing units

10,00złPlastic, pendulum bearing units are used mainly in food industry applications where high resistance to chemicals used to clean equipment ...Brackets and handles for sidebands

10,00złAn important element of each conveyor is an appropriate system of sidebands to ensure proper guidance of products during transport.Tripods, bipods, support heads

10,00złComponents for conveyors’ construction of System Plast company are a very wide range of products, which are used as elements ...Drive and passive wheels for modular belts

10,00złModular belt wheels are produced in 2 versions, for belt drive (drive wheels) and for mounting on non-driven return shafts (passive ...Plastic plate chains

10,00złOur offer includes high quality plate chains manufactured by SystemPlast and made of the most modern plastics.Drive and passive chain wheels

10,00złPlate chain wheels are manufactured in 2 versions, for chain drive (drive wheels) and for mounting to non-driven return shafts (passive ...Steel plate chains

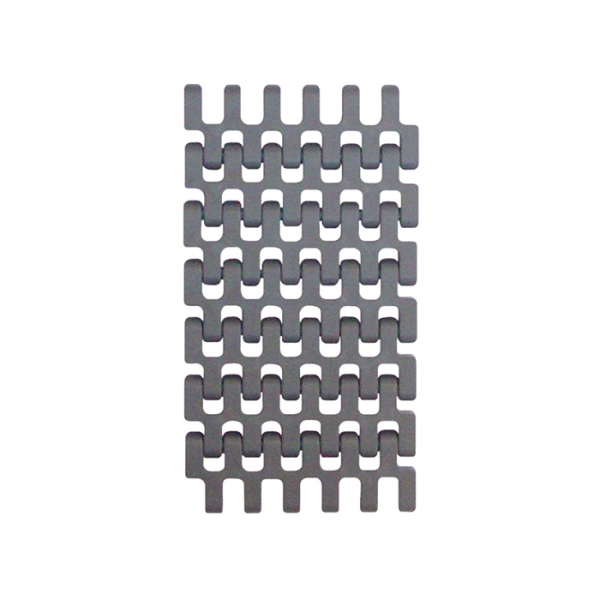

10,00złArchimedes' wide offer includes many products from the category of components for the construction of machinery, involving in particular elements ...General-purpose straight running modular belts

10,00złGeneral-purpose modular belts and belts for the transport of food products are used for the transport of packaged products as ...Slides

10,00złSlides from the Systemplast production offer are used in the construction of conveyors as a supporting and guiding elements for ...Components for conveyors

10,00złModern transport systems, in addition to their basic transport function, perform a number of other tasks.

Zobacz również

Tripods, bipods, support heads

10,00złComponents for conveyors’ construction of System Plast company are a very wide range of products, which are used as elements ...General-purpose arched modular belts

10,00złGeneral-purpose modular belts and belts for the transport of food products are used for the transport of packaged products as ...Steel plate chains

10,00złArchimedes' wide offer includes many products from the category of components for the construction of machinery, involving in particular elements ...General-purpose straight running modular belts

10,00złGeneral-purpose modular belts and belts for the transport of food products are used for the transport of packaged products as ...Cast iron bearing supports

10,00złCast iron bearing units are used in all equipment where any transmission is present.Pendulum feet

10,00złAdjustable, pendulum feet are a commonly used component in the construction of industrial machinery, equipment and conveyors.Components for conveyors

10,00złModern transport systems, in addition to their basic transport function, perform a number of other tasks.Drive and passive chain wheels

10,00złPlate chain wheels are manufactured in 2 versions, for chain drive (drive wheels) and for mounting to non-driven return shafts (passive ...Plastic plate chains

10,00złOur offer includes high quality plate chains manufactured by SystemPlast and made of the most modern plastics.Drive and passive wheels for modular belts

10,00złModular belt wheels are produced in 2 versions, for belt drive (drive wheels) and for mounting on non-driven return shafts (passive ...