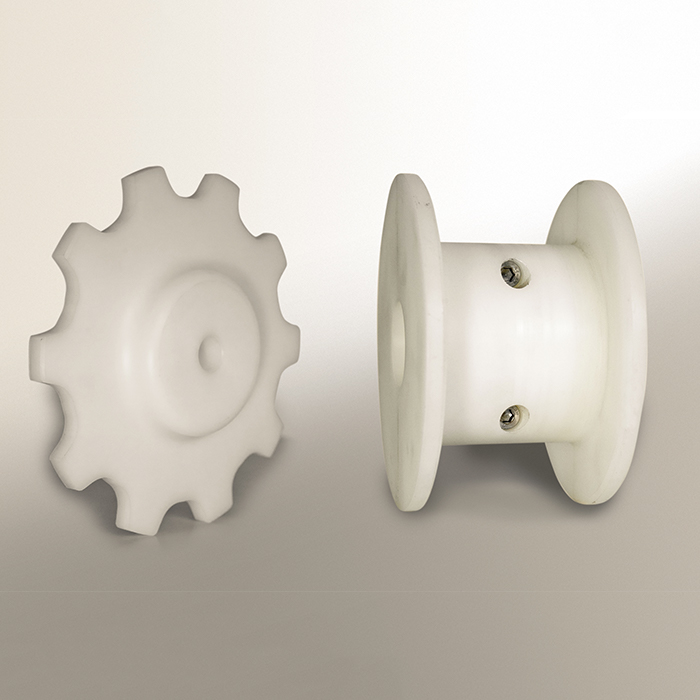

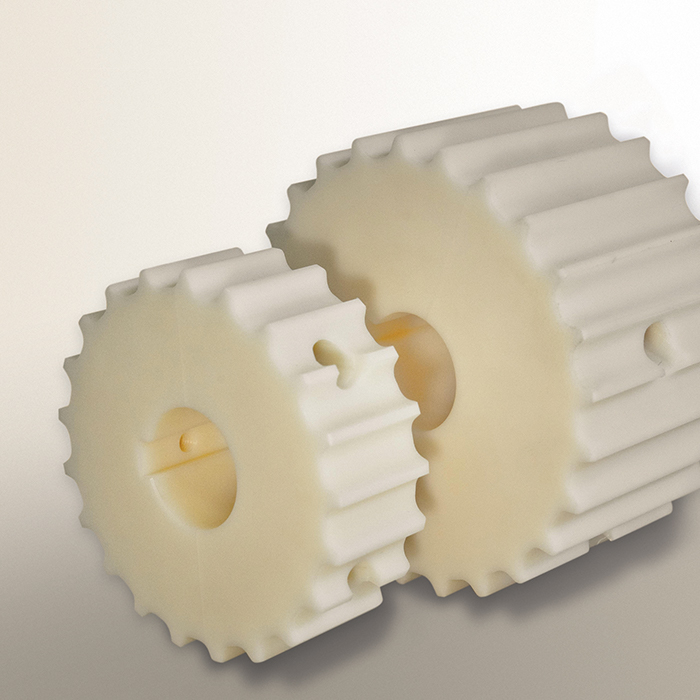

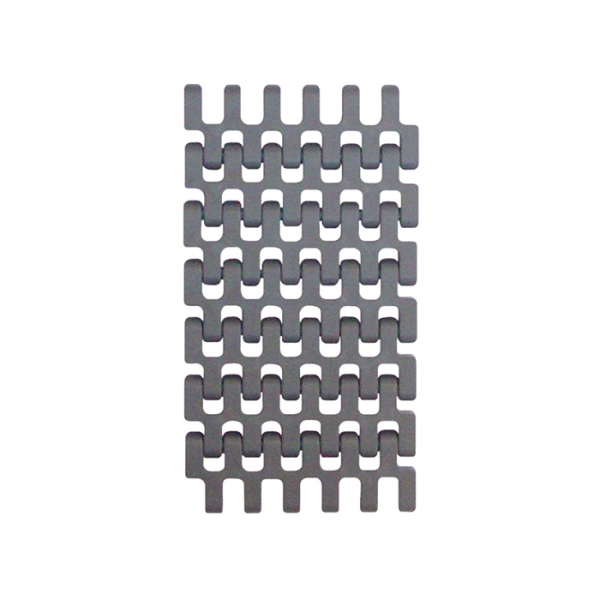

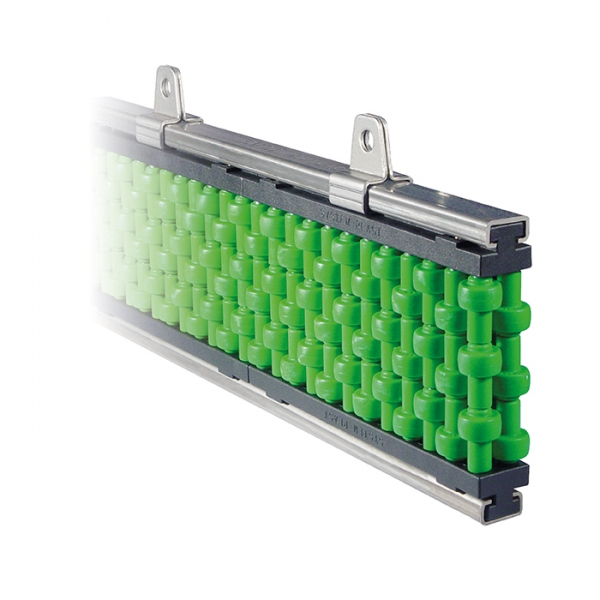

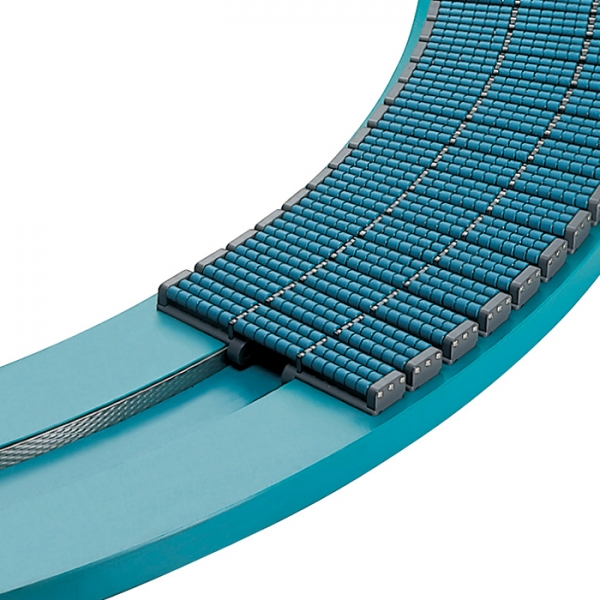

Plate chain wheels are manufactured in 2 versions, for chain drive (drive wheels) and for mounting to non-driven return shafts (passive wheels).

Category: Elements of conveyors’ construction Tags: Drive and passive chain wheels, drive wheels, koła bierne System Plast, Koła napędowe i bierne do łańcuchów, koła napędowe System Plast, Koła System Plast, passive wheels, RegalRexnord, system plast, systemplast, Usuń taksonomię Komponenty do budowy przenośników Komponenty do budowy przenośników, Приводные и пассивные цепные колеса

Attachments

ŁAŃCUCHY I TAŚMY MODUŁOWE 09_2012.pdfPlate chain wheels are manufactured in 2 versions, for chain drive (drive wheels) and for mounting to non-driven return shafts (passive wheels).

The offer includes wheels for all plastic and metal chains produced by Systemplast Company.

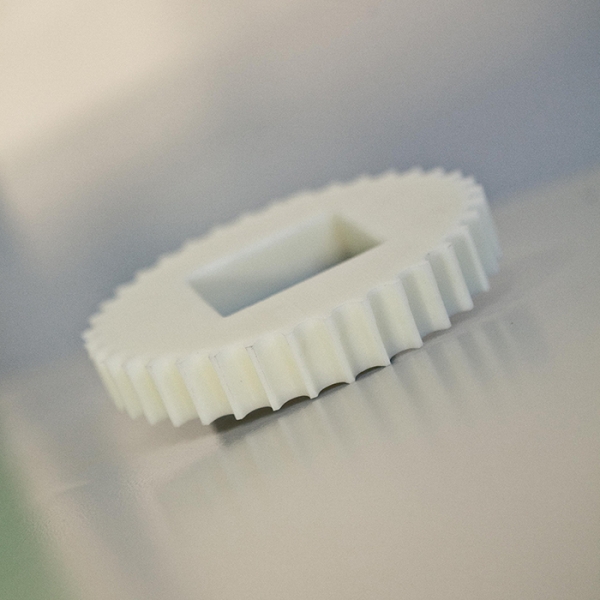

Versions of produced wheels:

- split wheel – easy installation on shafts without the need of their disassembly,

- non-split wheel – required disassembly of shafts.

Production range:

- number of teeth on the wheel (depending on the series) from 13 to 34,

- outer diameters of wheels from D56mm to D360mm,

- holes’ diameters for round shafts from d18mm to d45mm,

- holes’ sizes for square shafts from 25mm x 25mm to 90mm x 90mm.

- drive wheels with openwork design enabling automatic removal of dirt (optimal life, double groove for wedge),

- return wheels (passive) with an acetal sliding bushings or with ball bearings (sturdy construction, open surface shortens the cleaning or washing process).

Materials used for the production of wheels:

- reinforced polyamide for injection-manufactured wheels,

- polyamide PA6 for wheels processed on numerical machines from full shaft or plate material,

- carbon steel C45,

- metal wheel elements (screws, nuts, pins, bushings), stainless steel, nickel-plated steel or brass.

Interactive online catalogue with editing of DXF, 3D drawings:

Zobacz również

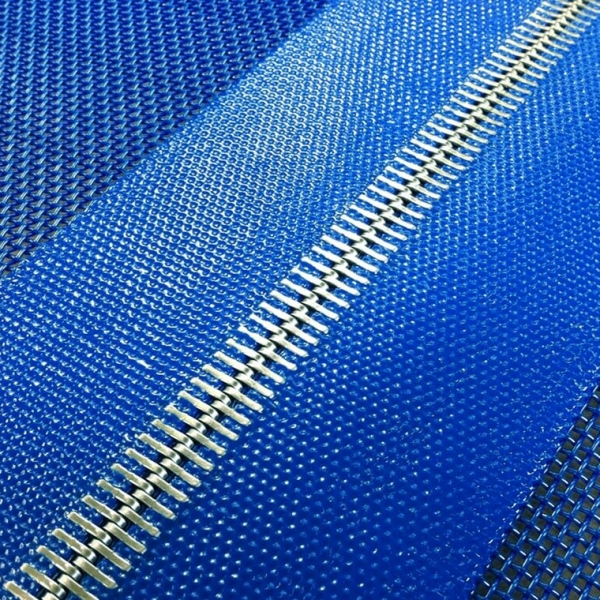

Filtering nets

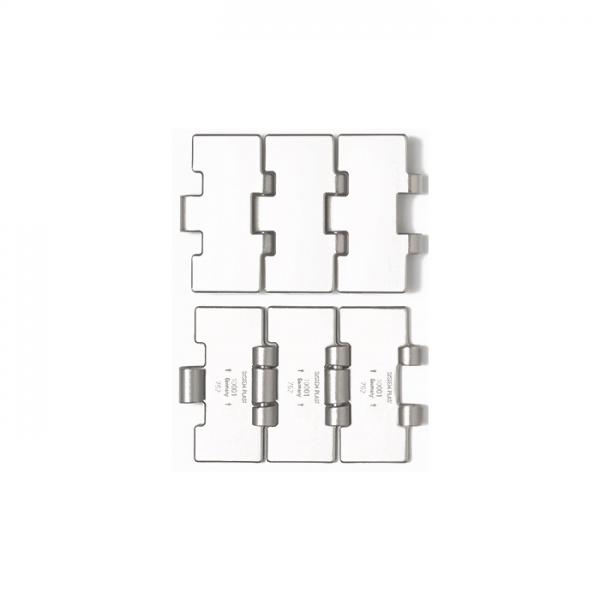

10,00złNet filtering belts are made of polyester fibres and used in many industrial processes.Steel plate chains

10,00złArchimedes' wide offer includes many products from the category of components for the construction of machinery, involving in particular elements ...General-purpose arched modular belts

10,00złGeneral-purpose modular belts and belts for the transport of food products are used for the transport of packaged products as ...Cast iron bearing supports

10,00złCast iron bearing units are used in all equipment where any transmission is present.Brackets and handles for sidebands

10,00złAn important element of each conveyor is an appropriate system of sidebands to ensure proper guidance of products during transport.Stainless steel bearing supports

10,00złBearing units made of stainless steel are used mainly in aggressive environments, in the food and pharmaceutical industries and wherever ...General-purpose straight running modular belts

10,00złGeneral-purpose modular belts and belts for the transport of food products are used for the transport of packaged products as ...Sidebands

10,00złProperly selected system of sidebands ensures high efficiency of the conveyor, shortens the time of rearming and increases the quality ...Drive and passive wheels for modular belts

10,00złModular belt wheels are produced in 2 versions, for belt drive (drive wheels) and for mounting on non-driven return shafts (passive ...Bearing supports for rollers

10,00złThe elements produced by Markes Company are used in the construction of driven and gravitational roller conveyors as well as ...

Zobacz również

Tripods, bipods, support heads

10,00złComponents for conveyors’ construction of System Plast company are a very wide range of products, which are used as elements ...Slides

10,00złSlides from the Systemplast production offer are used in the construction of conveyors as a supporting and guiding elements for ...Sidebands

10,00złProperly selected system of sidebands ensures high efficiency of the conveyor, shortens the time of rearming and increases the quality ...Components for conveyors

10,00złModern transport systems, in addition to their basic transport function, perform a number of other tasks.General-purpose arched modular belts

10,00złGeneral-purpose modular belts and belts for the transport of food products are used for the transport of packaged products as ...Pendulum feet

10,00złAdjustable, pendulum feet are a commonly used component in the construction of industrial machinery, equipment and conveyors.Brackets and handles for sidebands

10,00złAn important element of each conveyor is an appropriate system of sidebands to ensure proper guidance of products during transport.Chain and belt guides

10,00złThe guides are used to guide modular belts and plate chains in a targeted way.Filtering nets

10,00złNet filtering belts are made of polyester fibres and used in many industrial processes.Bearing units

10,00złPlastic, pendulum bearing units are used mainly in food industry applications where high resistance to chemicals used to clean equipment ...