The inclined, L-type and Z-type elevating conveyors ensure the transport of products between different machine levels (height difference between levels from 0.5m to 6m).

Attachments

przenośniki wznoszące KFG-P 2000.pdfThe inclined, L-type and Z-type elevating conveyors ensure the transport of products between different machine levels (height difference between levels from 0.5m to 6m). The supporting element is a modular belt, PVC belt, PU belt or a homogeneous toothed PU Volta belt (Pasitive Drive SD, DD, DDSP). The working width of the belts strictly depends on the transported product, the assumed conveyor capacity and the application type. It usually ranges from 300mm to 1400mm.

Conveyor belts are usually equipped with additional elements such as:

- side constraints (height from 20mm to 100mm),

- trucks (height from 10mm to 150mm),

- guide wedges K8, K10, K13, K17.

These accessories prevent the product from falling through and ensure that it is lifted together with the belt, thus ensuring the appropriate transport capacity of up to several tons per hour. Conveyors’ construction is made of metal sheets and structural profiles connected by welding or screwing, then it undergoes silde process. Depending on the requirements, the conveyors may have covering systems, drip trays, hoppers and receiving trays. Electrical equipment and drives used according to customer requirements:

- control boxes with speed control,

- gearmotors with a higher IP degree, covered with epoxy paint or stainless steel.

The base for conveyors is usually made up of levelling construction feet and, in addition, rollers enabling easy movement of the device. The conveyors are accompanied by the necessary technical documentation required by the regulations and the manufacturer’s declaration.

Zobacz również

Conveyors with modular belt

10,00złModular belt conveyors are used for bulk products (loose), unit and bulk packaging. Modular belt is a supporting element.Research stands

10,00złThe modern labour market requires graduates of schools and technical studies to have knowledge of modern solutions and the ability ...Assembly tables

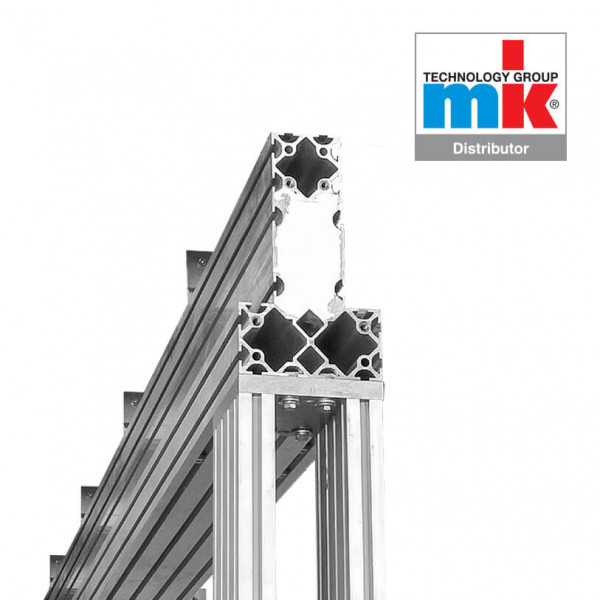

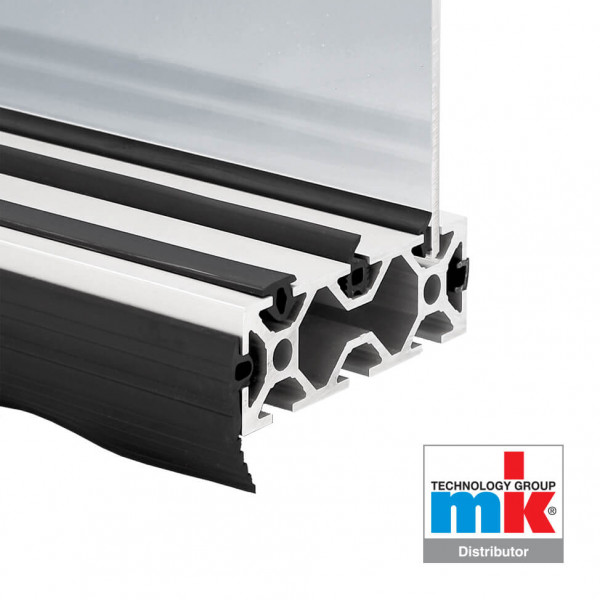

10,00złThe MK’s profile system allows for easy and quick construction of workstations used in production, assembly or repair processes.Machine’s casings and structures made of aluminium profiles

10,00złAluminium constructional profiles are ideal for frames and machine’s casings.Saw feeders with cutting length measurement

10,00złConveyors for special applications. They serve as feeders for cutting parts.Assembly components

10,00złArchimedes remains the exclusive distributor and partner of Mk Technology Group since 2011.Turntables

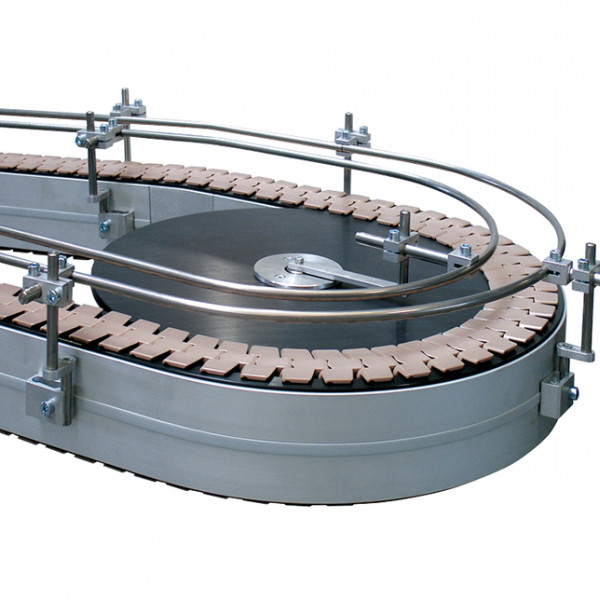

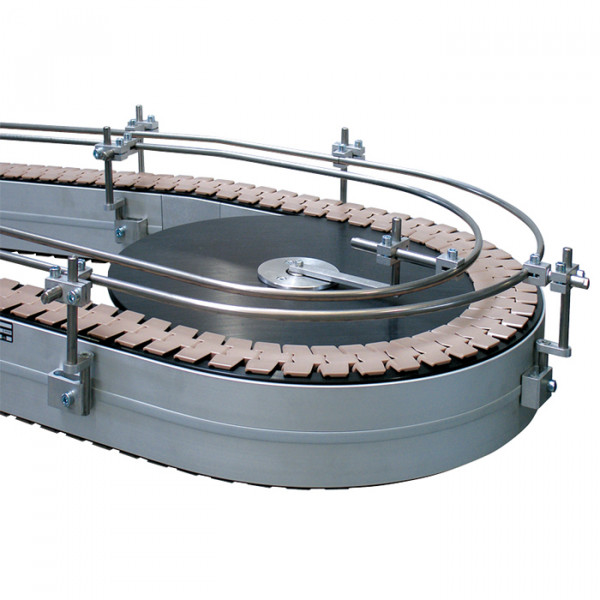

10,00złWe make turntables on the basis of MK Technology’s aluminium profiles. Projects are developed by our Design Department or ...Professional profiles

10,00złMk Technology Group is present on the European and American market. It is one of the leading suppliers of mechanical ...Versamove Standard System

10,00złMK's many years of experience in internal transport technology resulted in the introduction of a comprehensive transfer system.Conveyors with plate chain

10,00złPlate chain conveyors are usually used to transport bottles, cans, cardboard boxes and other tiny and narrow items.

Zobacz również

Conveyors with modular belt

10,00złThe plastic modular belt allows the transport of materials with temperatures up to 105°C.Inspection conveyors

10,00złInspection conveyors are designed primarily for transporting bulk products. During the transport (at low speed), the service personnel are able ...Profile system’s accessories

10,00złSealants and cover profiles, plugs, panels and filler nets, conveyor rollers, pneumatic connections, electrical accessories, bumpers and stops, sliders and ...Conveyor belts with aluminium construction

10,00złBelt conveyors are the widest and most commonly used group of conveyors.Conveyors with modular belt

10,00złModular belt conveyors are used for bulk products (loose), unit and bulk packaging. Modular belt is a supporting element.Turntables

10,00złWe make turntables on the basis of MK Technology’s aluminium profiles. Projects are developed by our Design Department or ...Versamove Plus System

10,00złMK's many years of experience in internal transport technology resulted in the introduction of a comprehensive transfer system.Assembly tables

10,00złThe MK’s profile system allows for easy and quick construction of workstations used in production, assembly or repair processes.Versamove Ultra System

10,00złMK's many years of experience in internal transport technology resulted in the introduction of a comprehensive transfer system.