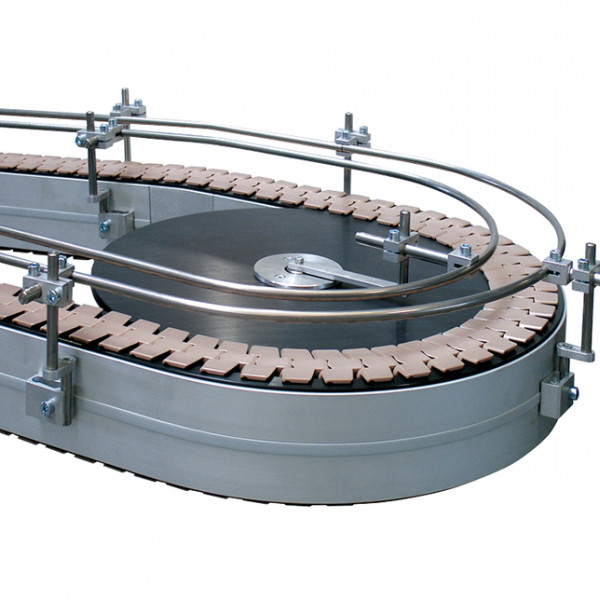

Conveyors of this type are used to transport packed products.

Attachments

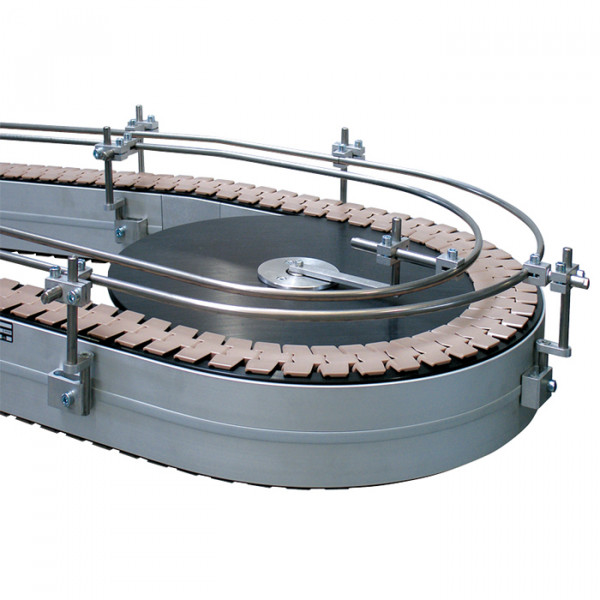

SBF-P.pdfConveyors of this type are used to transport packed products. They are most often used in the bottling industry (transport of cans, glass bottles, PET bottles, cartons) and in fruit, vegetable and fish processing (transport of jars, cans). The supporting element is a plate chain (plastic or metal) with a width from 32mm to 304mm. The supporting structure of the conveyors is made of profiled sheets with a polished external surface, connected by welding or screwing with metal elements.

The width of the conveyor depends on the product and application and usually ranges from 50mm to 1000mm.

Conveyors are built as single-row for single products or multi-row for bulk products (e.g. buffer tables).

Length from 600mm to 15000mm, height from 300mm to 1300mm, load up to 100 kg/mb.

Fixed or variable speed drive (mechanical adjustment of the variator, electrical adjustment of the inverter).

Drive or return shafts are supported in bearing units with pendulum bearings. The conveyor design also includes support and side guide systems selected according to product size and application requirements. They ensure proper product guidance and prevent the product from tipping over or falling out of the conveyor. These can be steel rods, flat bars with PE caps, metal profiles with plastic element, roller bands (beaded). Supports are usually made by means of a pipe or profiles mounted on bipods and tripods with leveling feet for the conveyor. Other additional equipment of conveyors according to customer requirements. Conveyors are built for straight sections and working with arched sections.

Zobacz również

Profile system’s accessories

10,00złSealants and cover profiles, plugs, panels and filler nets, conveyor rollers, pneumatic connections, electrical accessories, bumpers and stops, sliders and ...Sliding guides

10,00złProwadnice liniowe ślizgowe VST marki mk Technology, zwane równieżmodułami liniowymi występują w dwóch wielkościach ...Versamove Plus System

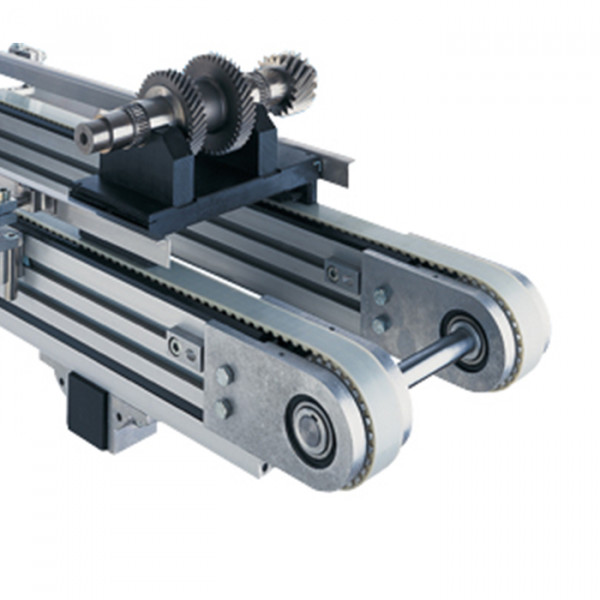

10,00złMK's many years of experience in internal transport technology resulted in the introduction of a comprehensive transfer system.Conveyors with gear belts

10,00złConveyors with gear belts are made with one, two or even several belts.Stainless steel belt conveyors

10,00złBelt conveyors commonly used to transport unit or bulk products.Versamove Standard System

10,00złMK's many years of experience in internal transport technology resulted in the introduction of a comprehensive transfer system.Assembly components

10,00złArchimedes remains the exclusive distributor and partner of Mk Technology Group since 2011.Versamove Ultra System

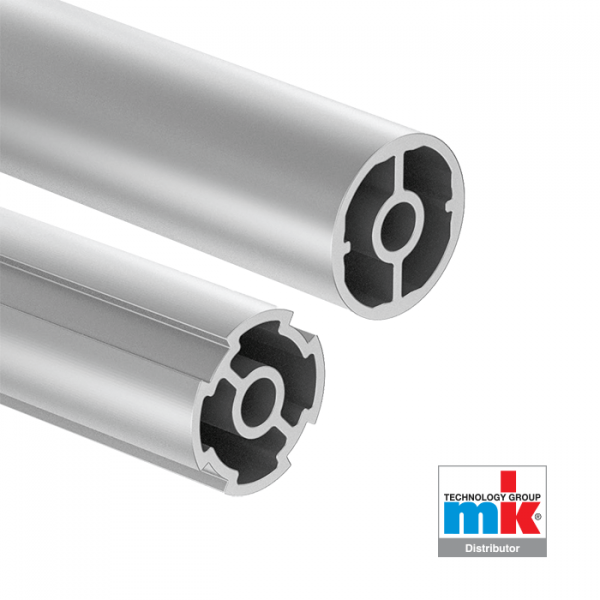

10,00złMK's many years of experience in internal transport technology resulted in the introduction of a comprehensive transfer system.Round profiles – D28 tube system

10,00złD28 tube system - economical design and easy installation of round profiles

Zobacz również

Conveyors with modular belt

10,00złThe plastic modular belt allows the transport of materials with temperatures up to 105°C.Stainless steel elevating conveyors

10,00złThe inclined, L-type and Z-type elevating conveyors ensure the transport of products between different machine levels (height difference between levels ...Professional profiles

10,00złMk Technology Group is present on the European and American market. It is one of the leading suppliers of mechanical ...Conveyors with plate chain

10,00złPlate chain conveyors are usually used to transport bottles, cans, cardboard boxes and other tiny and narrow items.Stainless steel belt conveyors

10,00złBelt conveyors commonly used to transport unit or bulk products.Research stands

10,00złThe modern labour market requires graduates of schools and technical studies to have knowledge of modern solutions and the ability ...Versamove Standard System

10,00złMK's many years of experience in internal transport technology resulted in the introduction of a comprehensive transfer system.Round profiles – D28 tube system

10,00złD28 tube system - economical design and easy installation of round profilesAssembly components

10,00złArchimedes remains the exclusive distributor and partner of Mk Technology Group since 2011.