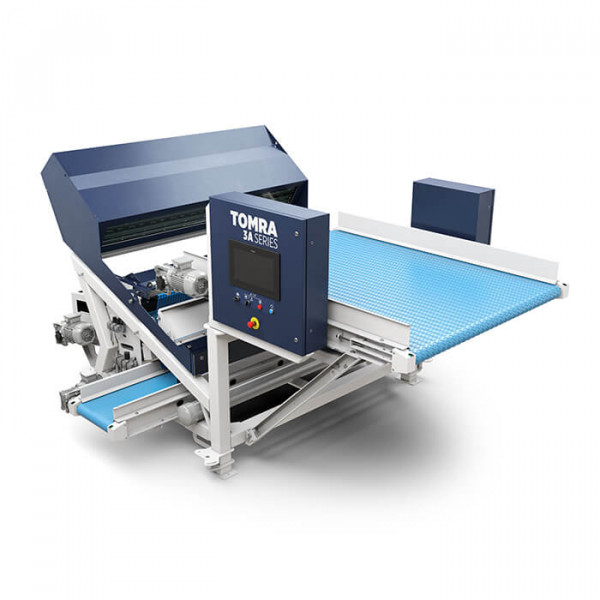

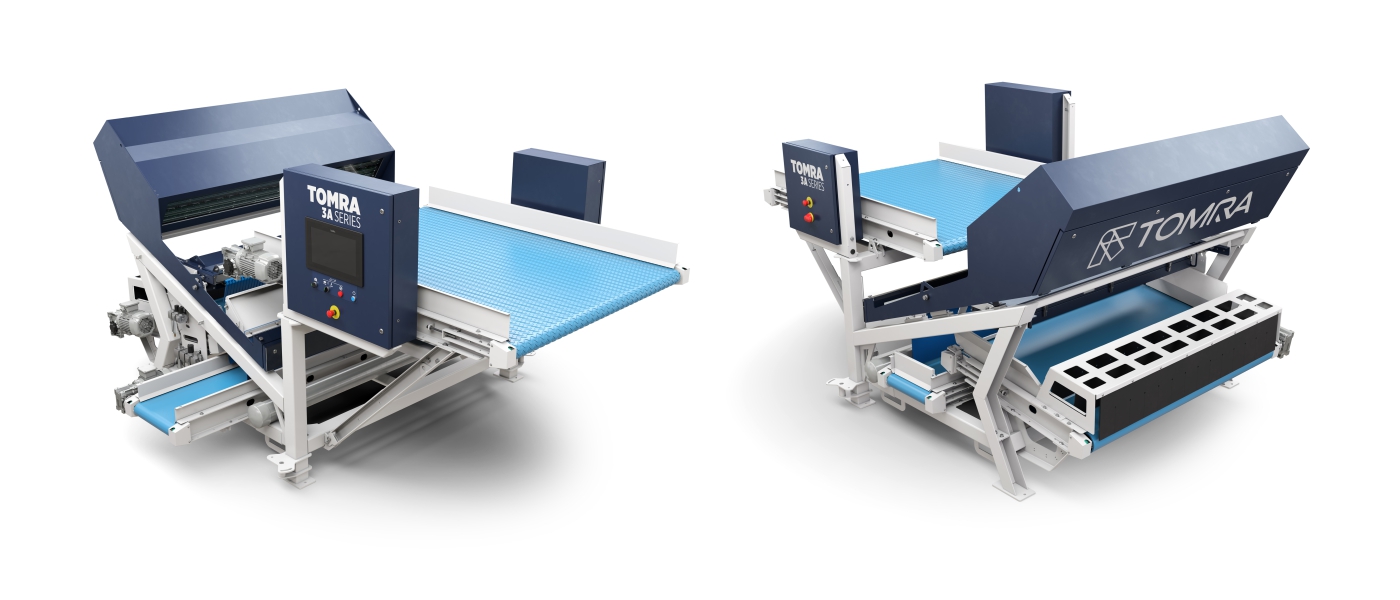

TOMRA is one of the largest manufacturers of fries sorting equipment. 75% of the fries produced worldwide are sorted and processed by TOMRA machines.

TOMRA is one of the largest manufacturers of fries sorting equipment. 75% of the fries produced worldwide are sorted and processed by TOMRA machines. The company offers the widest range of sorting solutions available in the food industry. The range includes advanced optical sorters for many applications, from fresh produce to processed food.

TECHNOLOGY AT YOUR SERVICE

The manufacturer of sorting machines offers numerous solutions for sorting fresh, whole, sliced, flaked, diced and frozen potatoes. TOMRA optical sorters separate the product in whole or processed form, i.e. fries, roasted potatoes, chips and other potato forms.

Precise sorting technologies based on sensors enable the product to be sorter, taking into account the defects of the sorted biological characteristics, analysing them in terms of structure, size, shape, density of unknown material and colour of the potato. The machines use unique near infrared sensors (NIR) to scan each individual item ‘in flight’. This allows for an undisturbed view of the product during high capacity sorting.

Thanks to the technology used, these machines sort the product for the removal of defective products -discoloured, rotten, green, blue. Moreover, they eliminate unknown materials such as plastic, stones, glass, sticks, etc. TOMRA also offers steam peeling systems. The performance of these systems ranges from 1000 to 50,000 kg/h.

One of TOMRA’s flagship products is the equipment for sorting fries and peeled potatoes. Following the Belgian tradition of french fries, the company has developed solutions to analyse the fries in terms of length, shape or curvatures.

BENEFITS:

The use of TOMRA sorting machines translates directly into:

- high productivity and repeatability of 1-50 tons per hour

- very low level of production waste

- low water consumption

- reliability in continuous operation 24/7

- food safety

- guarantee of quality and repeatability

IT IS AN INVESTMENT THAT PAYS FOR ITSELF IN A FLASH!

TOMRA’s food sorters are among the most efficient machines available on the market worldwide. Optical sorters control millions of individual items per hour, recovering as much as 5-10% of the yield.

Check the technical parameters in the brochure below.

Watch the Tomra’s Sorters video..

Find out what sorter is right for your business!

+48 601 357 661 – Paweł Janiga

+48 601 457 944 – Maciej Lubański

Zobacz również

Material cutting systems

10,00złThe Erhardt Leimer’s cutting system of the ELCUT BTA80, BT05 or BT02 series is used to cut the edges ...Assembly components

10,00złArchimedes remains the exclusive distributor and partner of Mk Technology Group since 2011.Arched conveyors

10,00złArched conveyors are used to change the direction of transport in the horizontal plane. Maschinenbau Kitz offers several types of ...Research stands

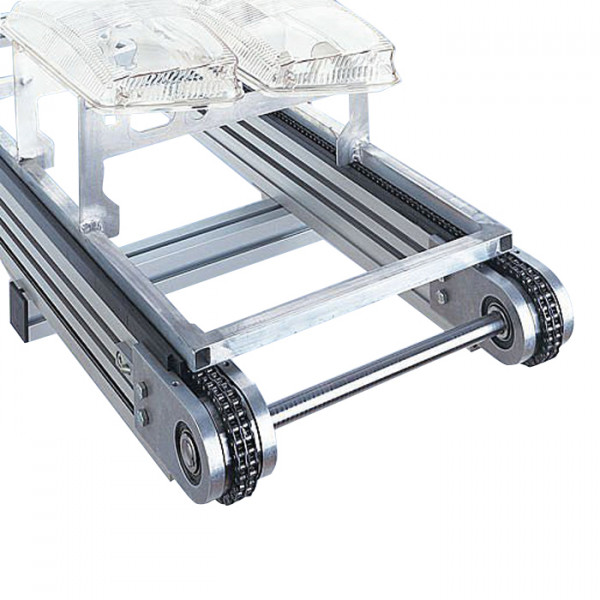

10,00złThe modern labour market requires graduates of schools and technical studies to have knowledge of modern solutions and the ability ...Conveyors with modular belt

10,00złThe plastic modular belt allows the transport of materials with temperatures up to 105°C.Ball tables

10,00złAdjustable ball tables are most often used in the logistics industry to transport products such as cartons, boxes or flat-bottomed ...Elevators

10,00złMK Technology's elevator system is a vertical cargo transport system. It enables delivery of more than 250 kg on a 600 x 800 ...Assembly tables

10,00złThe MK’s profile system allows for easy and quick construction of workstations used in production, assembly or repair processes.

Zobacz również

Professional profiles

10,00złMk Technology Group is present on the European and American market. It is one of the leading suppliers of mechanical ...Versamove Ultra System

10,00złMK's many years of experience in internal transport technology resulted in the introduction of a comprehensive transfer system.Assembly components

10,00złArchimedes remains the exclusive distributor and partner of Mk Technology Group since 2011.Versamove Standard System

10,00złMK's many years of experience in internal transport technology resulted in the introduction of a comprehensive transfer system.Control and measurement systems

10,00złThe Erhardt Leimer's NYSCAN vision print control system allows direct control and repeatability of the process.Turntables

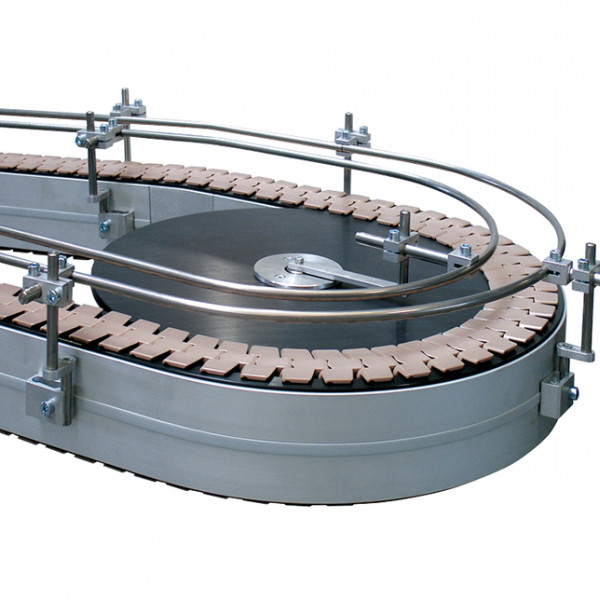

10,00złWe make turntables on the basis of MK Technology’s aluminium profiles. Projects are developed by our Design Department or ...Conveyors with plate chain

10,00złPlate chain conveyors are usually used to transport bottles, cans, cardboard boxes and other tiny and narrow items.Ball tables

10,00złAdjustable ball tables are most often used in the logistics industry to transport products such as cartons, boxes or flat-bottomed ...Educational tables

10,00złArchimedes Ltd is a manufacturer of educational stands based on aluminium profiles for mechatronic laboratories.Material guidance systems

10,00złErhardt Leimer is a world market leader in the production of material guidance systems.