PMI’s screw mechanisms consist of a spindle and a nut with a circular thread.

Attachments

katalog PMI_2013 - śruby kulowe.pdfPMI’s screw mechanisms consist of a spindle and a nut with a circular thread.

The nut contains balls that move in a closed circuit. Ball screws and ball nuts are among the most commonly used screw mechanisms in industrial and precision CNC machines. They enable the change of rotary motion into progressive motion and vice versa. They are characterized by high precision and high efficiency coefficient. Rolled ball screws are an alternative to trapezoidal screws. The screw is made during the rolling process, while the nuts are made in the same way as for polished screws. Nuts without preload and with maximum axial blacklash are interchangeable, i.e. different types of nuts can be used on the same ball screw.

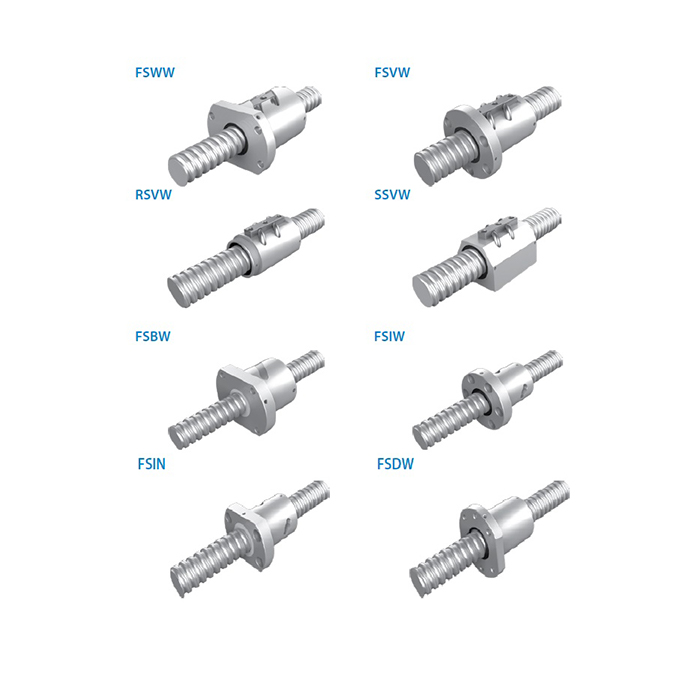

The range includes the following series: FSIN, FSWW, FSVW, RSVW, FSBW, SSVW, FSIW, FSDW and FSDN to DIN 69051.

Basic parameters of rolled ball screws:

- thread’s pitch: 4 – 40 mm

- thread’s diameter: 12 – 50 mm

- length: up to 6000 mm

- accuracy class: C5 – C10

- can be made with left-side thread (diameters 25 and 32 mm)

- single or double nut

Zobacz również

Cables’ guides

10,00złChain wires’ guides provide controlled movement and protection of electric, hydraulic, pneumatic and optical cables.Cooled ball screws

10,00złScrews with internal cooling circuit have been designed by PMI especially for high speed and heavy duty applications.Polished ball screws

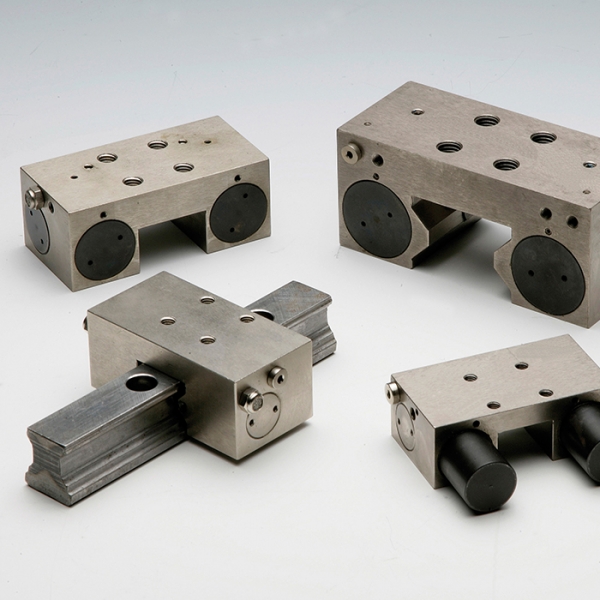

10,00złPMI's screw mechanisms consist of a spindle and a nut with a circular thread. The nut contains balls that move ...Bearing blocks for screws

10,00złBearing blocks manufactured by SUNG-IL MACHINERY are designed for ball and trapezoidal screws.Sliding guides

10,00złProwadnice liniowe ślizgowe VST marki mk Technology, zwane równieżmodułami liniowymi występują w dwóch wielkościach ...Guides with bearing rollers

10,00złThe guides with CTS bearing rollers are made on the basis of aluminium profiles with steel, chrome-plated and polished rods.Precision ball guides PMI

10,00złPMI’s precision ball guides carry the same loads and load capacity in all directions.Linear roller guides

10,00złPMI’s linear roller guides offer the highest rigidity and load capacity compared to other guides of the same size.Brake clapms

10,00złBrake clamps for linear guides are connected to the trucks and allow clamping on the guide’s rail.

Zobacz również

Bearing blocks for screws

10,00złBearing blocks manufactured by SUNG-IL MACHINERY are designed for ball and trapezoidal screws.Precision ball guides PMI

10,00złPMI’s precision ball guides carry the same loads and load capacity in all directions.Sliding guides

10,00złProwadnice liniowe ślizgowe VST marki mk Technology, zwane równieżmodułami liniowymi występują w dwóch wielkościach ...Polished ball screws

10,00złPMI's screw mechanisms consist of a spindle and a nut with a circular thread. The nut contains balls that move ...Guides with bearing rollers

10,00złThe guides with CTS bearing rollers are made on the basis of aluminium profiles with steel, chrome-plated and polished rods.Linear roller guides

10,00złPMI’s linear roller guides offer the highest rigidity and load capacity compared to other guides of the same size.Brake clapms

10,00złBrake clamps for linear guides are connected to the trucks and allow clamping on the guide’s rail.Cooled ball screws

10,00złScrews with internal cooling circuit have been designed by PMI especially for high speed and heavy duty applications.Cables’ guides

10,00złChain wires’ guides provide controlled movement and protection of electric, hydraulic, pneumatic and optical cables.